[vc_row row_type=”row_center_content” bg_position=”left top” bg_repeat=”no-repeat” row_text_color=”row_text_select” border_style=”solid” padding_top=”10″ padding_bottom=”10″][vc_column width=”1/2″][vc_single_image image=”4979″ border_color=”grey” img_link_target=”_self” img_size=”blog-large”][vc_column_text]

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text]Client: Shaker Heights F.D. Ladder Truck

Year Completed: 2017

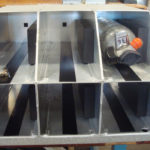

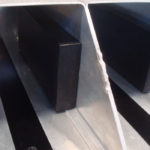

New Pierce 107′ Ladder Truck for Shaker Heights Fire Department, Shaker Heights Ohio. Sensible Products Inc. mounted all equipment that was brought with the truck and also left space and mounts for equipment that wasn’t currently with the truck. This apparatus had mounting peg board throughout, so Chanl Panl boards were not needed. On the drivers side, all water flow mounts were mounted on the back wall behind a swing out panel. Mounts for storz fittings, couplings, and adapters were provided. In the lower section of this compartment, a black floor board and back board were added to a slide out tray and a Chanl Panl 2-sided divider was mounted here. This gave more room for mounting water flow equipment on the Chanl Panl boards or nozzles on the floor board. In the next compartment, a full length shelf was cut in half and a black floor board and plastic welded divider was added here. This left room on the left side of the compartment for larger items that extended above the shelf height. A sledge hammer was mounted here and mounts for a pry bar were supplied. In the last compartment on the drivers side, a black floor and back board were added in a slide out tray for extrication tools and accessories. A cutter, spreader, and ram were mounted. A tool pocket was added on the back board to hold batteries. Also in this compartment, an additional shelf with Turtle Tile was added to hold air bags. In the rear of the apparatus, portable lights and batteries/chargers were secured by a plastic welded divider. Also in this rear compartment, Sensible Products modified an existing air bottle storage box to prevent the rolling of the bottles in an area that was too large. Custom plastic spacer blocks were added to each bottle compartment to shrink up the space and prevent the bottles from rolling around. On the passengers side of the apparatus, equipment was mounted in 5 compartments. In the last compartment, a black floor board was added and 2 extinguishers were secured with straps. In the fourth compartment, a black floor board was added and a generator was secured with a strap. Additional straps were provided here for a RIT bag and vent fan. In the third compartment, a black floor board and aluminum strip were added to hold the high rise pack. All forcible entry tools were mounted in this compartment including: a trash hook, 2 halligans, flat head axe, sledge hammer, and bolt cutters. In the second compartment, a black floor board was added on a slide out tray and 2 saws were mounted here. A pocket was mounted on the side wall for saw parts and a saw blade post was mounted on the opposite side wall to hold extra blades. An additional shelf was added in this compartment to hold the sawzall. In the first compartment, a slide out tray was removed from this area and a custom plastic welded divider and shelf assembly was added here. A custom plastic welded box with a handle was made to catch the oil dry and allow the box to be filled and carried to the scene. Also mounted in this compartment was a rex tool and water extinguisher. Two lights were mounted in the cab. Custom plastic welded dividers were made for each of the 4 air bottle compartments over the wheel wells to prevent bottles in this area from rolling around. Each compartment will now hold 2 bottles separated by a divider. In the cross lay area of the apparatus, a custom plastic welded hose tray/ tool holder was made. This custom item was added to hold 4 long handle tools in their own plastic tube and there is space above on the shelf for additional hose to be carried. This tray was designed to match the current hose trays already on the apparatus. All equipment was labeled with red/white tags. This truck was completed in 5 days.

[/vc_column_text][vc_column_text]

- Match your equipment to our mounting products listed in our catalog. Custom mounts are available upon request. We will ship all mounting products complete along with mounting hardware. This will allow you to plan, layout, and mount all equipment at your facility.

- Contact us for help designing boards or configuring cabinets based on your equipment list. We will ship complete boards to you, ready for installation.

- Send us your apparatus and accompanying equipment and we will do all the layout, fabrication, and installation. Your apparatus will be completely outfitted and ready to Go In Service when it leaves our facility! Contact us for outfitting large fleets as well.

[/vc_column_text][/vc_column][/vc_row]